Archaeologists uncover ancient 'factory' used to produce coveted purple dye mentioned in Bible

Historians recently unveiled their findings about an ancient purple dye factory located in modern-day Israel — revealing a glimpse into life during biblical times.

In an article recently published in the journal PLOS One, historians announced the discovery of Tel Shiqmona, an archaeological mound south of the Israeli city of Haifa. The site is located on the coast of the Mediterreanean Sea.

Tel Shiqmona, the article’s authors say, “can unequivocally be identified as a specialized facility for large-scale and long-term production of the lucrative purple dye.”

HISTORIC MARYLAND CHURCH OPENS DOORS TO VISITORS 320 YEARS AFTER CLOSING DOWN

The site dates back as early as 1100 B.C., during the Iron Age. In Biblical terms, the site predated the reigns of Kings Solomon and David by over a century, and likely became more sophisticated over time.

“It is the only site in the Near East or around the Mediterranean – indeed, in the entire world – where a sequence of purple-dye workshops has been excavated and which has clear evidence for large-scale, sustained manufacture of purple dye and dyeing in a specialized facility for half a millennium, during the Iron Age,” the article describes.

“The number and diversity of artifacts related to purple dye manufacturing are unparalleled.”

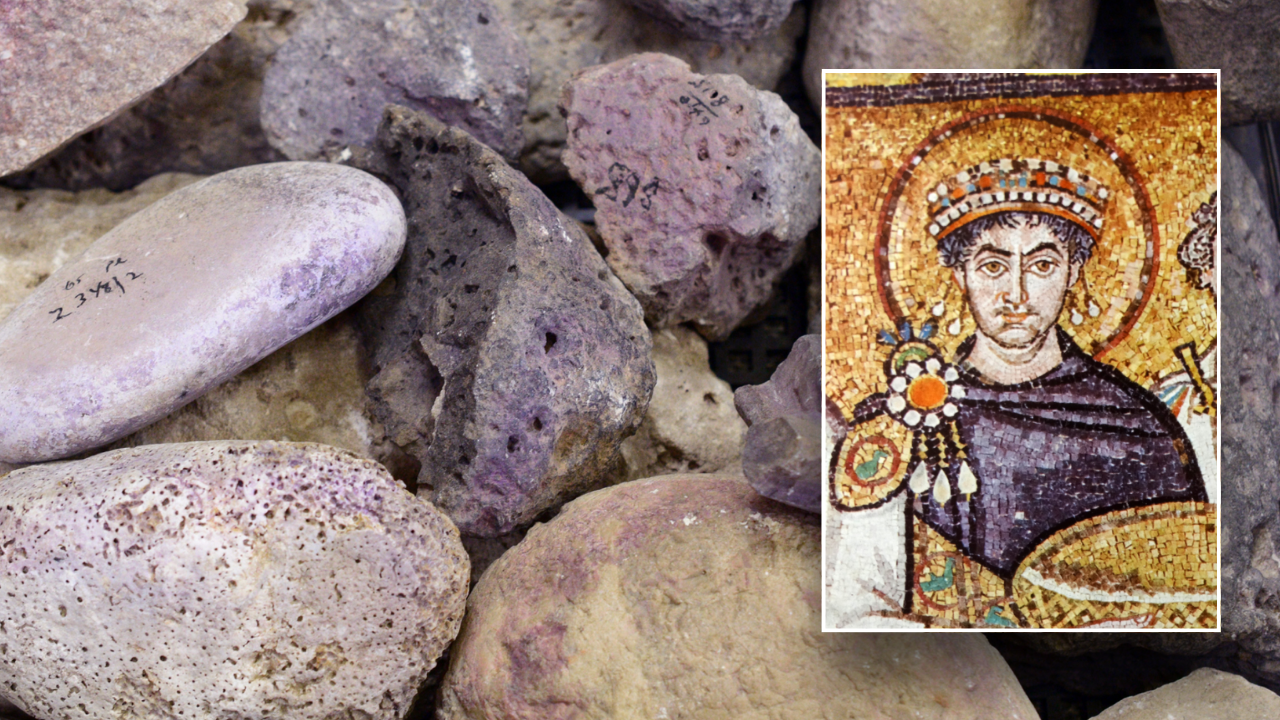

Pictures show fragments of vats with purple dye stains, as well as purple residue on various stone tools. What makes the site so unique is that it produced purple dye on an industrial scale – which historians previously thought was introduced by Romans in the first century A.D.

LONG-LOST CAPITAL OF ANCIENT CIVILIZATION MAY HAVE FINALLY BEEN UNCOVERED, ARCHAEOLOGISTS SAY: ‘UNIQUE FIND’

The dye, which was harvested by crushing the shells of certain mollusks, was highly valued in antiquity, and mentioned in the Bible several times. One biblical mention of purple dye occurs in Acts 16:14, which describes a female merchant.

“One of those listening was a woman from the city of Thyatira named Lydia, a dealer in purple cloth,” the verse reads. “She was a worshiper of God. The Lord opened her heart to respond to Paul’s message.”

In Mark 15:17, Jesus was dressed in purple cloth by his captors in order to humiliate him, as the color was associated with royalty.

For more Lifestyle articles, visit foxnews.com/lifestyle

“And they clothed him in a purple cloak; and after twisting some thorns into a crown, they put it on him,” the verse says.

At Tel Shiqmona, researchers used a variety of techniques, including chemical and mineralogical analyses, to understand each artifact that was uncovered. In an interview with New Scientist, archaeologist Golan Shalvi said the mollusks would secrete a greenish fluid when crushed, and the fluid would turn purple when oxidized.

“However, in order to transform it into an actual dye – one that chemically bonds with textiles – it must be processed into a solution through a complex series of chemical steps,” Salvi explained.

“It was an industrial site throughout most of the Iron Age, without monumental architecture or any particular beauty or elegance,” he added. “I imagine it as a very smelly place – especially to a modern nose – since the production process emitted a terrible odor. I picture wool fleeces dyed in various shades drying outside and inside the buildings, which may have given the site a purplish-reddish-blue hue.”

The team of analysts found that the factory at Tel Shiqmona both produced purple dye and then dyed fibers and fleeces, as opposed to simply producing dye.

“The size and opening of the vats would have allowed the dipping of the fleeces or fibers into the vats,” the article explains.

“Given their substantial weight when full, it is unlikely that the vats were intended to be moved, nor could they be tilted. Producing the dye in these very large vessels and then transferring it to other containers for dyeing (at Shiqmona or elsewhere) does not seem to be a plausible reconstruction of the process.”

“Therefore, we conclude that the entire manufacture, from harvesting the snails to dyeing, was conducted at the site, and that dye-production and dyeing were conducted in one container – apparently a rather efficient process.”