If you want to understand Steinel Ammo, start with the phrase stamped on everything they do: “Dedicated to Every Round.” That isn’t just marketing talk — it’s their core philosophy. Steinel Ammunition is for shooters who care.

At Steinel, there is only the good stuff. There are no levels of ammo quality, such as “match” or “range.” Whether it’s for self-defense, hunting, or target shooting, every round is produced to the same exacting standards because premium ammunition isn’t just a product line; it’s their entire mission. That’s what I noticed most during my visit last year when I toured their facility. But more on that later.

Who Is Andy Steinel?

That mindset originates directly from leadership. Andy Steinel, the founder, embodies this approach in shooting, engineering, and accountability. In 2015, Steinel Ammo was started in Andy’s basement, where he loaded small batches of remanufactured ammo. His late father inspected each round before Andy took them to local (and not-so-local) gun shows.

What began as a basement operation quickly expanded, driven by shooters who valued the quality. Within four years, Steinel Ammunition moved into its first commercial space in Twinsburg, Ohio. Two years later, it expanded into its current Twinsburg facility. Today, Andy continues to oversee all aspects of the operation.

Filling the Gap

As for why Steinel was founded, Andy noticed a disconnect between the promises made to shooters and what they actually received. Many manufacturers reserve their top efforts for a “match” label, neglecting other products.

Steinel chose a different path from the start, aiming to create ammunition that embodies precision, consistency, accuracy, and dependability in every cartridge. A satisfaction guarantee underscores this dedication, because genuine confidence comes from standing behind your product.

Steinel’s Processes

What truly sets Steinel Ammo apart from competitors is its extensive testing and quality control processes. Their partner network provides access to hundreds of firearms, from .25 ACP to .50 BMG, ensuring reliable ammunition performance across a wide variety of platforms. Throughout production, testing is continuous and rigorous.

Primer seating depth, cartridge length, powder charge, crimp, and shoulder bump are all checked so frequently that production may be halted every 20 rounds, depending on the caliber. Tolerances are kept extremely tight, allowing for adjustments before anything falls outside SAAMI specifications.

Accuracy and terminal performance are equally important. Pistol self-defense ammo is tested at realistic ranges (21-feet, hunting pistol rounds at longer distances (50 yards), and rifle cartridges at a minimum of 100 yards. For penetration and expansion, Steinel uses Type A Ordnance Gelatin that meets FBI standards, because lives and ethical kills depend on reliable, objective results. Velocity and pressure are also meticulously measured. Loads are developed using precise powders, dependable bullet weights, and data from trusted sources like Hornady, Speer, Lyman, Nosler, Alliant, and Hodgdon.

SAAMI standards impose strict requirements, and chronograph data are analyzed using rigorous statistical methods (for example, Steinel uses the Six Sigma principles). Ultimately, Steinel Ammo reflects an engineer’s dedication and a shooter’s needs — without compromise.

Visiting Steinel

Steinel Ammunition Co., as mentioned earlier, is located in Twinsburg, Ohio (a town known for its annual Twin Festival… yes, that’s a real event).

The building is unassuming, offering little hint that an ammunition company is based there. As you walk in, you’re welcomed by a small reception area where local shoppers can purchase ammo if they wish. Beyond Andy’s office and shared spaces, the building opens up into a large warehouse where the actual work takes place.

When visiting a large ammunition manufacturer such as Federal or Hornady, guests are greeted by large, automated machines that produce loaded ammunition at astonishing rates. That’s not the case at Steinel. While some automation is in place, ammunition is produced by individuals who test and fine-tune each machine to meet specifications.

Most ammo is loaded on Dillon 1050 and 1100 presses, arranged across several aisles. Each machine is configured to load a different product at any given time, using quality components that any handloader might choose, such as Starline brass, CCI primers, Hornady bullets, and more.

Currently, Steinel operates six automated presses and five manually operated ones. In 2026, the company plans to add two additional presses to increase production. Andy personally tests rounds from each batch in an indoor trap with an Ohler chronograph. This is to verify the velocity data, extreme spread, and standard deviation to ensure each is within its specified range. All data and recipes are carefully kept and stored for future use.

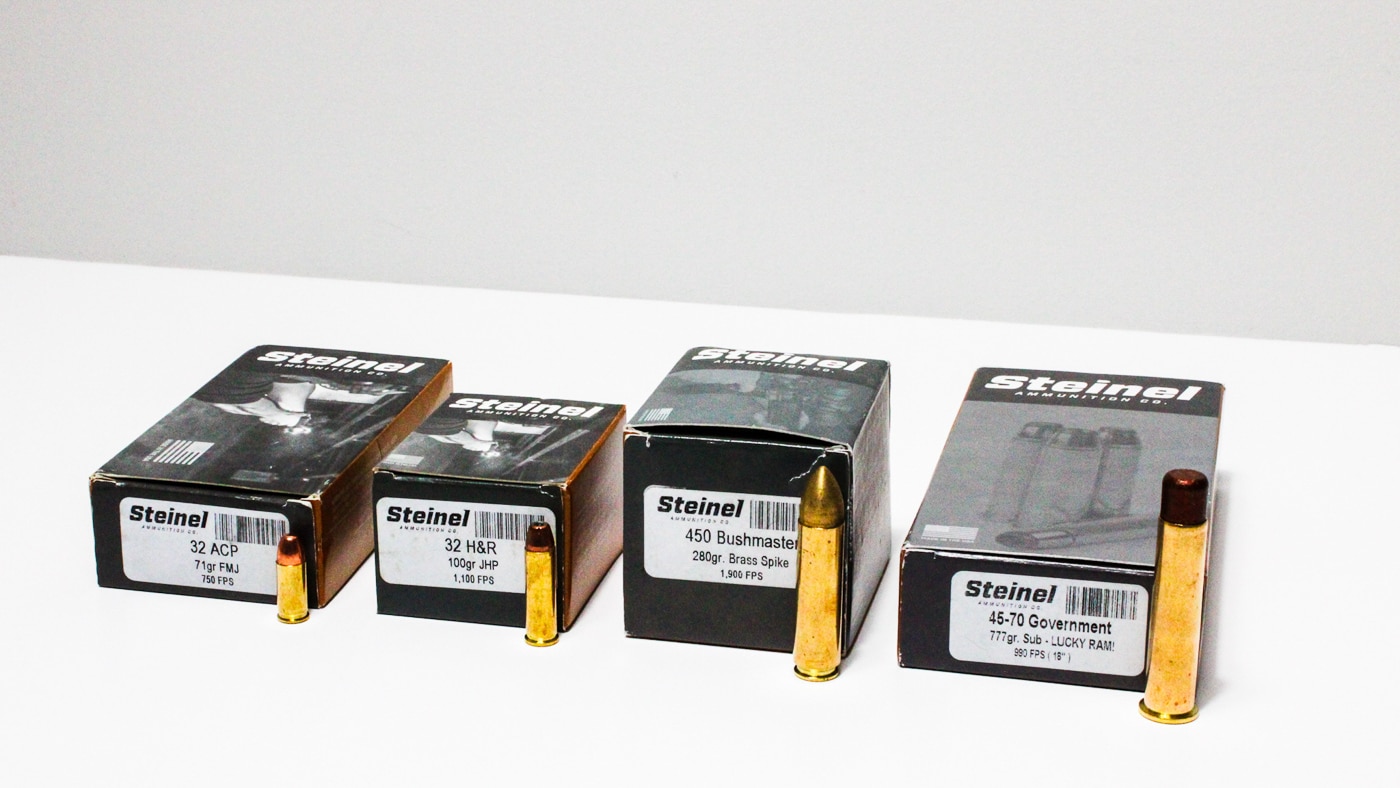

For specialty offerings, Steinel uses either a single-stage Rock Chucker or a Lyman turret press. They even have processes to cast their own bullets, including the 777-gr “Lucky Ram” bullet they developed for .45-70 Gov’t.

[Want to learn more about ammunition? Check out Robert Sadowski’s article on the four parts of a cartridge.]

Part of the space is leased to a machine shop, which might not matter to some, while others could see it as a smart way to offset operating costs. For Andy, however, this means they can develop their own molds, parts, and fixes on-site in real time — something other small ammunition companies lack.

In speaking with the staff, there is a deep sense of pride in what they do — they care. Every round loaded is important to them. They really stand behind the ethos of “Dedicated to Every Round.”

Once each round is loaded, it passes through a dedicated Quality Control station, where a technician checks it with a gauge to verify that everything is within spec. From there, the ammunition is packaged and ready to ship.

Ammo Offerings

What also sets Steinel apart from most other manufacturers is its commitment to preserving vintage and historical ammunition. This includes rifle calibers such as .30-06 M2 Ball, 7.5×55 Swiss, 8mm Lebel, 6.5x50mmSR Arisaka, 6.5×52 Carcano, 7.35x51mm Carcano, 8x56R Mannlicher, 303 British, 7.7mm Japanese, 7.62x54mmR, .30 Carbine, and others.

For pistols, the selection is equally extensive. This includes loads for 7.65 French Long, 7.26×25 Tokarev, 9mm Glisenti, 9mm Largo, .38/200, 8×22 Nambu, 45 Auto Rim, and .455 Webley.

[Confused by ammo jargon? Start with our article on What is Ball Ammunition?]

As someone passionate about vintage and historical firearms, I value knowing that a company exists to support this community. Owning historical arms is one thing, but having access to quality ammunition is another, and Steinel ensures enthusiasts like me still have ammunition options. For those still unsure, Steinel pressure-tests several of their cartridges, including 6.5x50mmSR Arisaka, 6.5×52 Carcano, and Trapdoor 45-70 Gov’t, to provide additional assurance.

While vintage and historical ammo are core to Steinel, an Ohio-based company, their most popular loads are aimed at Ohio deer hunters who are restricted to straight-wall rifle cartridges. As a result, .45-70 is among their best sellers. However, they don’t offer a single load; Steinel offers 21 SKUs. These range from Springfield Trapdoor-safe offerings to the 777-gr. “Lucky Ram.” They also carry options for .450 Bushmaster and .350 Legend, two other popular Ohio deer cartridges. There’s also a wide selection of revolver cartridges and defensive ammunition.

[Be sure to read Does It Matter What Grain Bullet You Use?]

What you won’t find from Steinel is cheap bulk offerings in chamberings like 9mm and 5.56mm. A company of Steinel’s size can’t compete with the big players, so why waste resources trying? Instead, Steinel focuses on what he does best — loading high-quality ammunition in unique cartridge offerings that few others offer.

Zooming Out

Andy Steinel and Steinel Ammunition are filling gaps left by larger companies. They are making ammo great again, one round at a time, with a level of care and attention to detail that’s hard to match. Their products are unique and serve a clear niche that many others don’t. If you’re looking for something specific, check out Steinel.

Editor’s Note: Please be sure to check out The Armory Life Forum, where you can comment about our daily articles, as well as just talk guns and gear. Click the “Go To Forum Thread” link below to jump in and discuss this article and much more!